Airfoil Blade Design

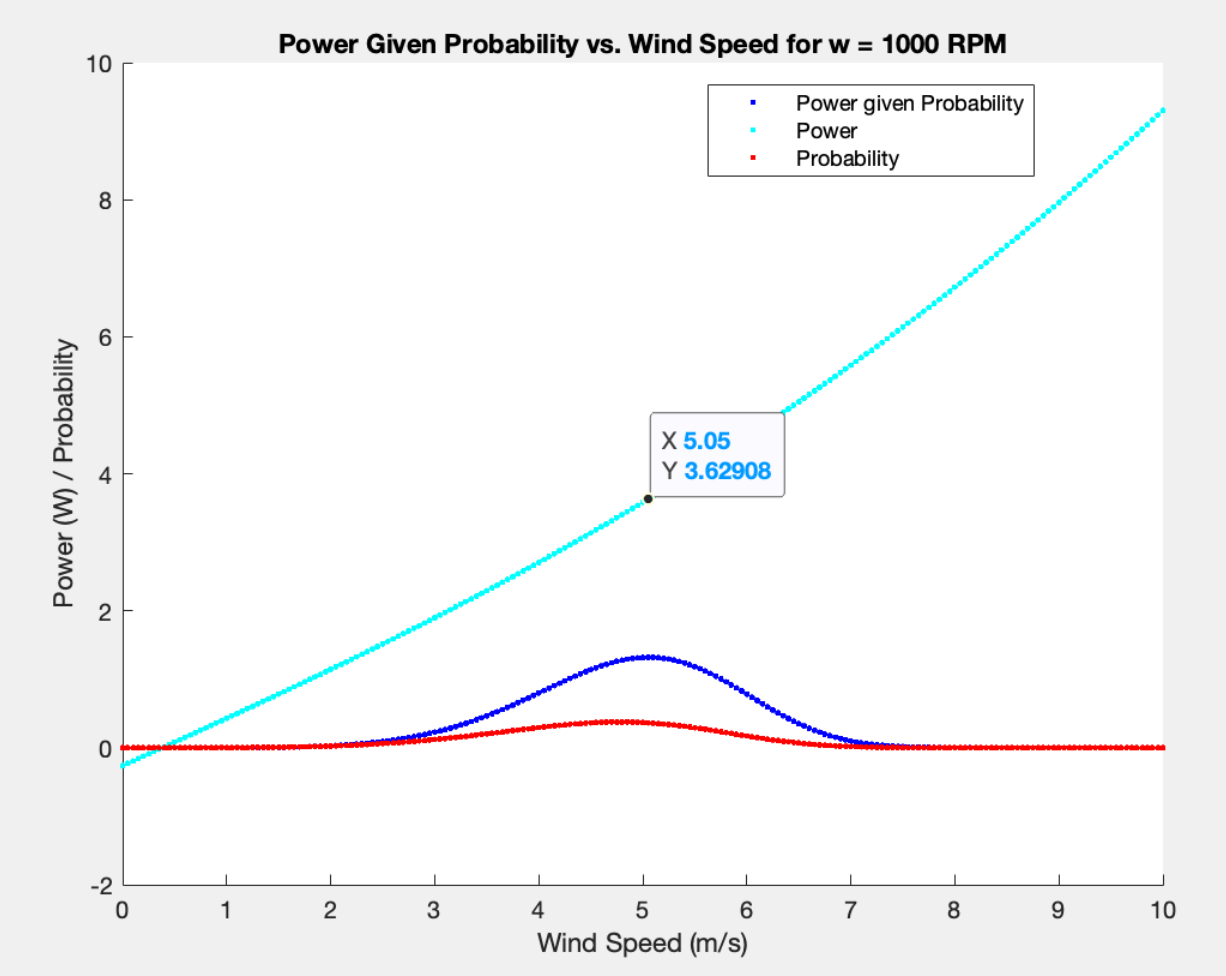

For MAE 4272 (Heat Transfer and Fluids Laboratory), we were asked to design an airfoil. The goal was to design an airfoil to operate at a fixed rotation rate, while operating in wind conditions told to us according to a Weibull distribution. We were asked to design this to learn how to optimize a design. I chose to optimize our design for power at our chosen rotation rate of 1000 RPM. Given our Weibull distribution, I calculated which wind speed to design for, which was determined to be 5.05 m/s. You can see the peak in this figure:

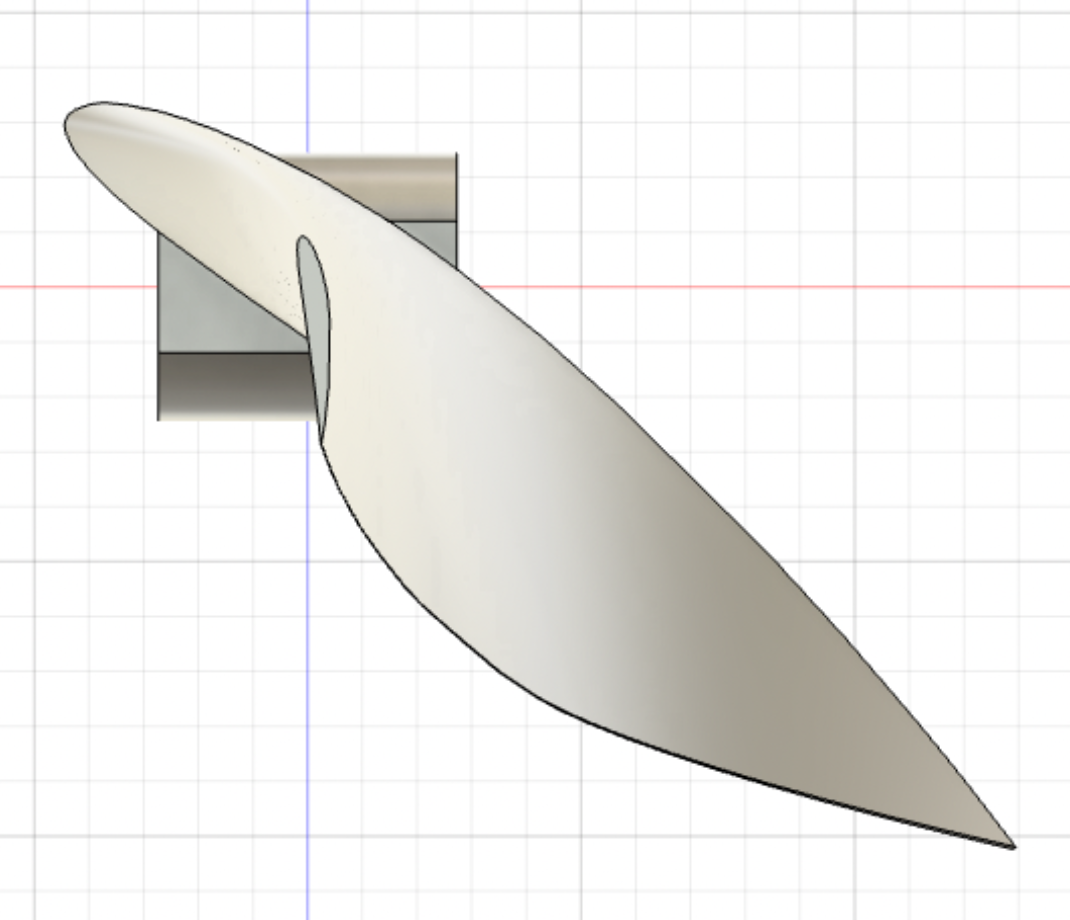

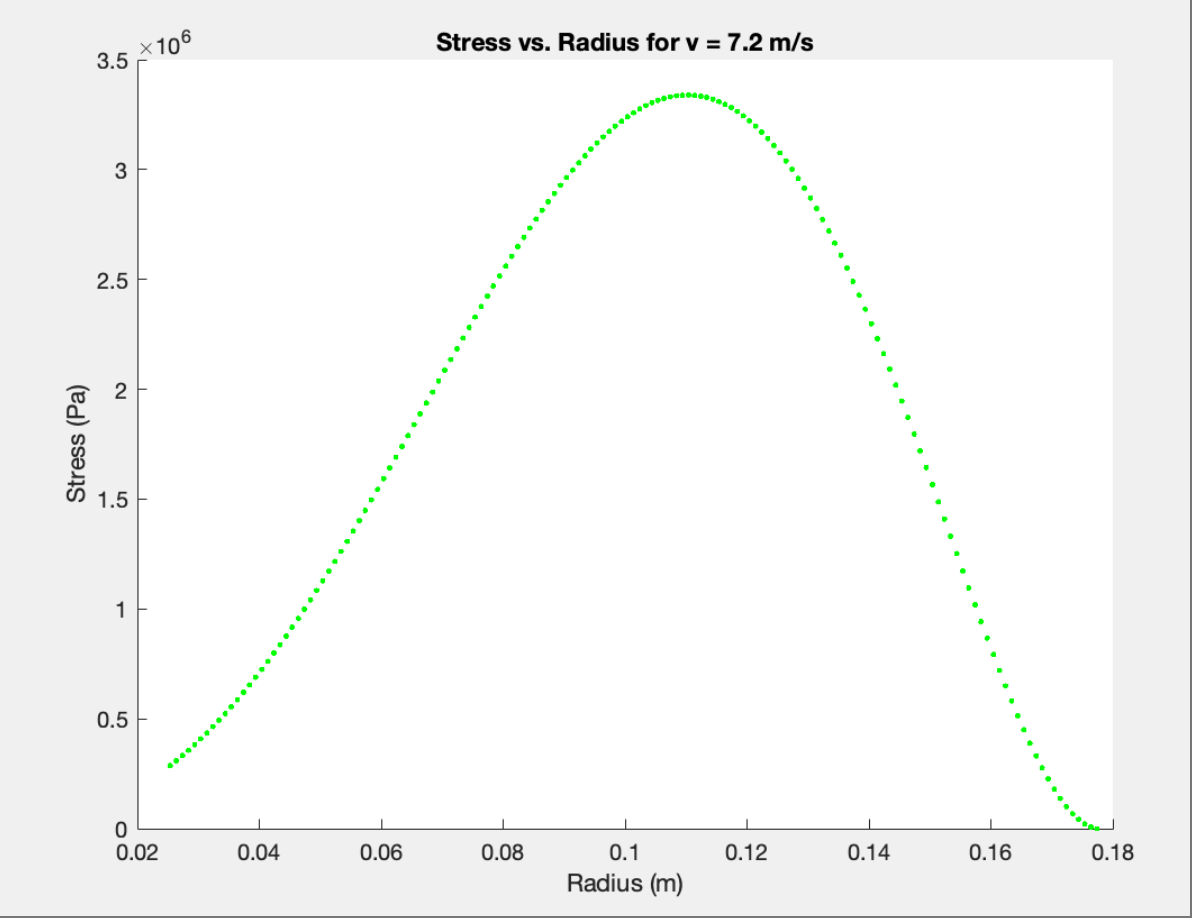

To optimize power, I designed to optimize our Cl/Cd ratio, which meant that I designed for a constant angle of attack of about 9.75 degrees. I twisted the pitch angle of the airblade to maintain this angle of attack. Then, I tapered our chord length to both maximize power within our limiting constraints. Here is an image of the expected stress on the airblade at the highest probable wind speed.

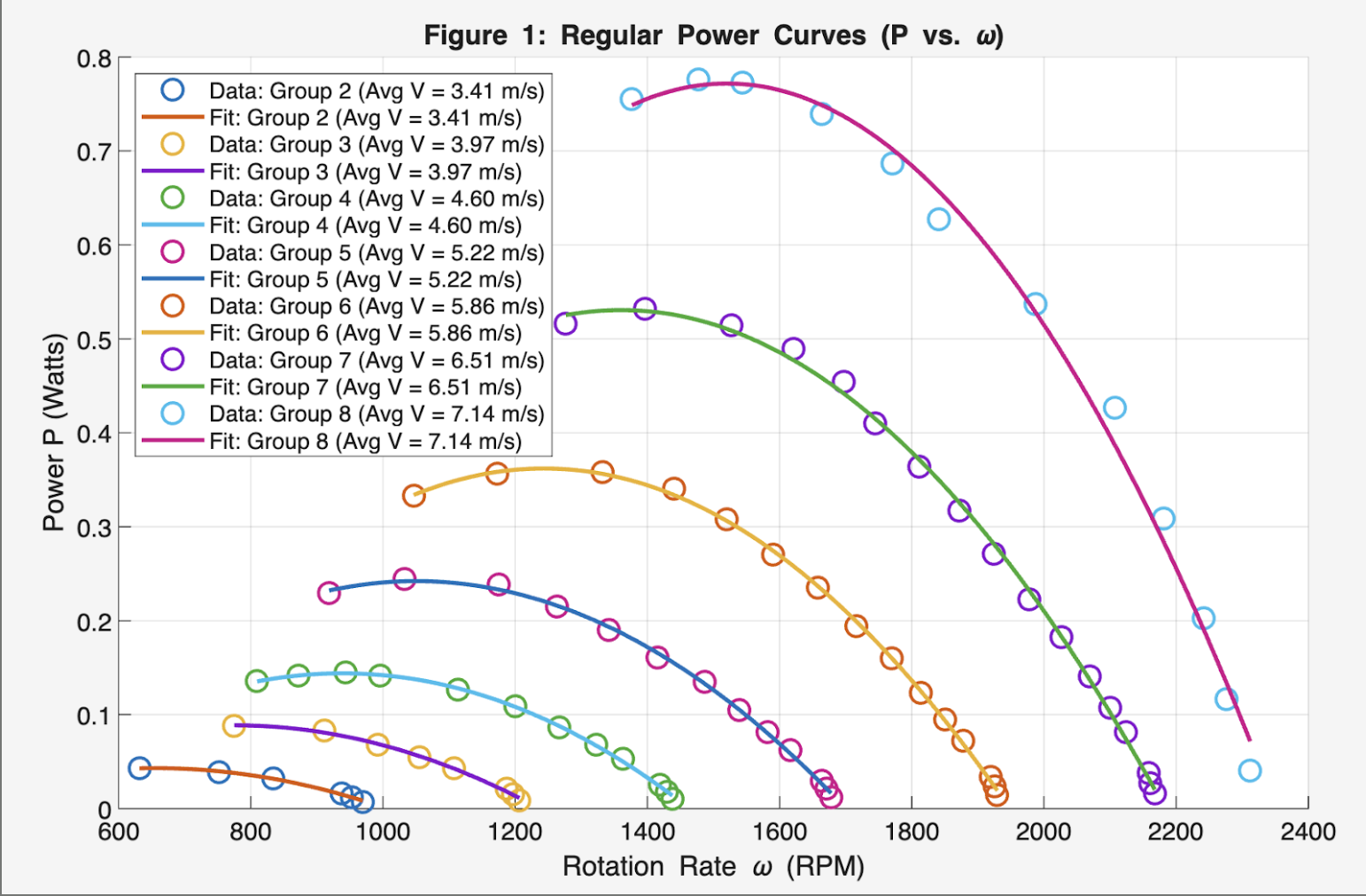

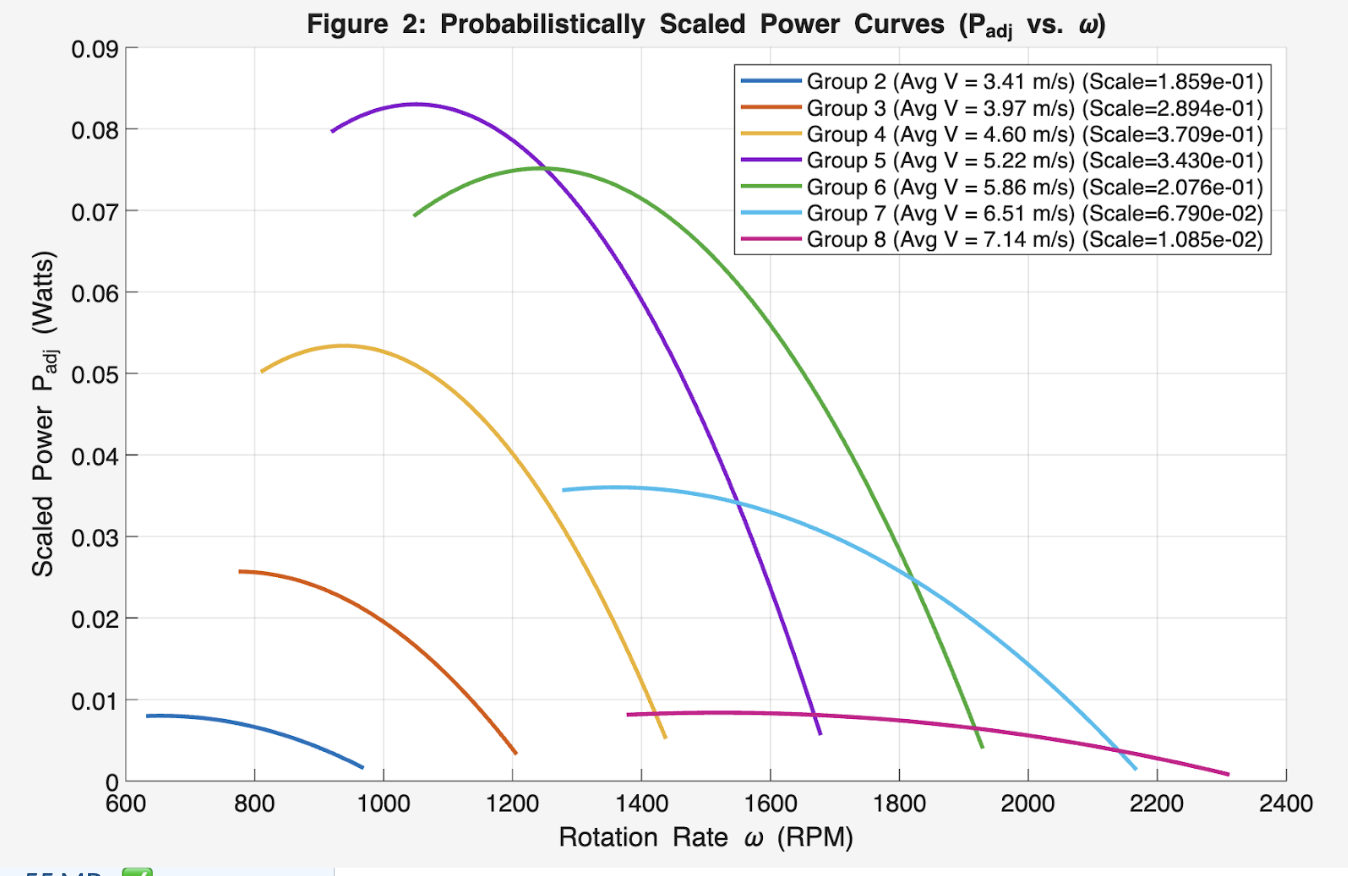

We tested the airfoils in a wind tunnel, obtaining power curves for the airfoils from 3.4 m/s to 7.1 m/s, our upper limit of likely wind speeds. Our results showed that our airfoils did generate the most power near 1000 RPM; however, the power generation was an order of magnitude less than expected. The power curves scaled by probability can be seen here: